How long can the gear pump of the hydraulic system work? From what aspects can it be analyzed?

Release date:2018-10-09 作者: Click:

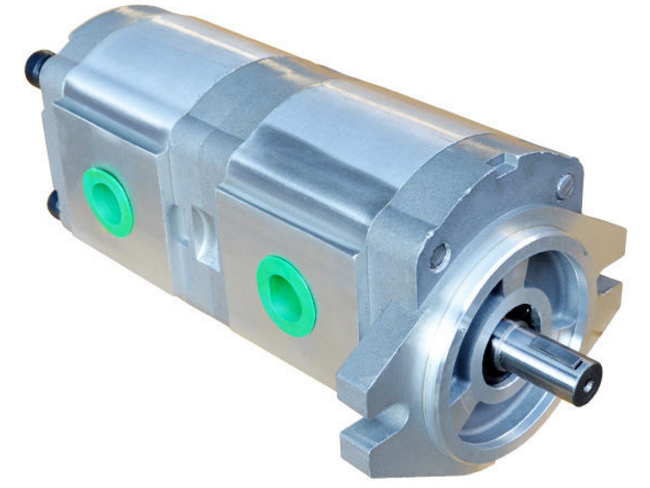

External gearing of hydraulic systemGear pumpThe design life of the gear pump is about 5000h, but it is generally unable to meet this requirement. So what factors affect the service life of the gear pump?Today, Yangtze River Hydraulics will take everyone to discuss it.

XNUMX. Design and selection of bearings

Gear pump design should consider its life.Most cases of gear pump scrapping are caused by bearing damage.At present, the ideal bearing material is the SF type composite material, which is based on steel plate, sintered copper mesh as the middle layer, and plastic (filled with tetrafluorohexene, modified polyoxymethylene) as the lubricating material of the friction surface.

Second, the end face gap problem

Hydraulic system gear pumps are often scrapped due to increased internal leakage, decreased volumetric efficiency, and decreased pressure during use.Gear end leakage accounts for 75% to 80% of the total leakage.Therefore, a reasonable end face clearance is very important.

Three, process reasons

In order to ensure a reasonable clearance between the front and rear cover of the gear pump, the processing and assembly of the gear pump are very important.The perpendicularity error between the two end faces of the gear and the core line of the hole shaft cannot exceed 0.01mm, and after being installed on the shaft, its axial direction should be in a floating state.In order to ensure the mutual position of the two shafts after assembly, the center distance error should not exceed 0.03mm when processing the front and rear bearing holes.In addition, breakage of the input shaft end is also a common phenomenon.For this reason, it is necessary to master the heat treatment process of the shaft to make it have a certain strength and hardness, and also have high impact toughness to prevent it from breaking.

Fourth, the reasonable selection of materials and components

In order to ensure that the gear pump has a reasonable clearance and fit during operation, the wear resistance of related materials is an important performance index.It is important to select reasonable materials and appropriate heat treatment processes.Oil seal leakage is also a common cause of scrap, so it is necessary to select a good material oil seal, and at the same time, pay attention to the tight fit between the oil seal and the bushing when processing and assembling.

Five, installation and use

Correct installation and reasonable use of gear pumps are also very important for prolonging the service life of gear pumps in hydraulic systems.When the gear pump input journal is connected to the motor shaft, the coaxiality error cannot exceed 0.01mm.Remember not to connect with straps.In addition, appropriate hydraulic oil should be selected according to the pump instruction manual, and a filter should be added at the entrance of the gear pump, and the hydraulic oil should be filtered and replaced regularly according to the working environment of the hydraulic system.

Through the introduction of the above editor, I think everyone knows that the main factors that affect the life of the gear pump are diversified. In the final analysis, in addition to the influence of the manufacturer's manufacturing process, the correct installation and rational use of the gear pump are very important.

The URL of this article: http://www.sccjyy.cn/news/395.html

Key words:Gear pump,High pressure gear pump,Gear pump manufacturers

Recently Viewed:

- Maintenance of hydraulic system of construction machinery and prevention of hydraulic cylinder cavitation failure

- A "Blue Book" was delivered to the door, tax companies gathered together to talk about party building and epidemic prevention work

- Reasons for the motor heating during the use of the gear pump

- What should I do if the piston rod in the hydraulic cylinder leaks out?

- The company organizes personnel to participate in fire safety training

- The requirements for hydraulic oil in the hydraulic system must be understood

- Hydraulic gear pump fault repair, bring you up knowledge

- How should the multi-way valve of a compressed garbage truck be repaired?

- Technical analysis of gear pump and plunger pump in mechanical engineering

- Changjiang Hydraulic participated in the XNUMXth West Expo

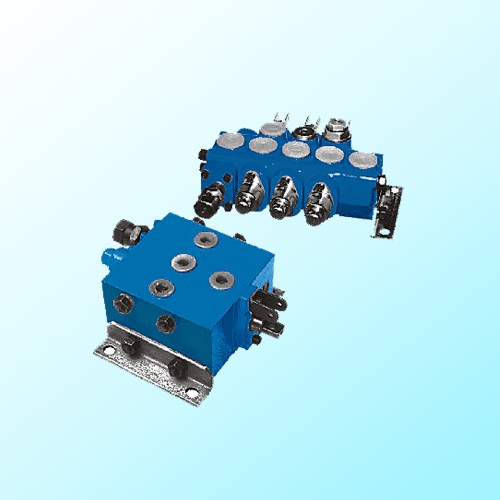

Related Products:

related news:

- Reasons for the motor heating during the use of the gear pump

- Contact strength and bending strength of gear oil pump

- What is the difference between a gear pump and a screw pump?

- What are the reasons for the gear pump oil seal being flushed out?

- Measures to reduce vibration and noise of gear pump

- What are the techniques to prevent the gear pump from clogging?

- What are the sealing methods for Luzhou hydraulic gear pumps?

- Causes of noise in gear pumps

- Press the "accelerator key" for epidemic prevention and production

- Changjiang Hydraulics won the title of "Demonstration Enterprise for Establishing Modern Enterprise System"