How to maintain the gear pump to make its life longer?

Release date:2019-01-08 作者: Click:

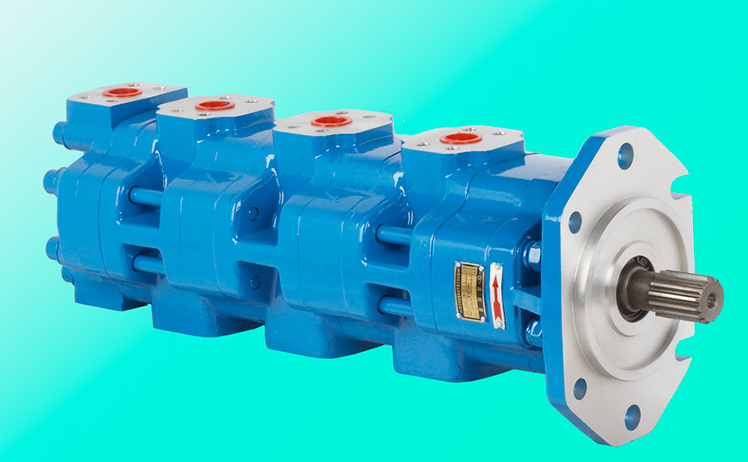

Gear pumpHow to maintain it to make it last longer?The gear oil pump uses two gears to mesh with each other to work, and the requirements for the medium are not high.The general pressure is below 6MPa, and the flow rate is relatively large.The gear oil pump is equipped with a pair of rotating gears in the pump body, one active and the other passive. The entire working chamber in the pump is divided into two independent parts by the meshing of the two gears. A is the suction cavity and B is the discharge cavity.When the gear oil pump is running, the driving gear drives the driven gear to rotate. When the gear is engaged to disengaged, a partial vacuum is formed on the suction side (A), and the liquid is sucked in.The sucked liquid fills the valleys of the gears and is brought to the discharge side (B). When the gears are engaged, the liquid is squeezed out to form a high-pressure liquid and is discharged out of the pump through the pump discharge port.

1. Frequent grease, electricThe oil drum pump runs at high speed and the grease is easy to volatilize. Therefore, the lubrication at the bearing must be kept clean and pay attention to replacement.

2. Note that the electric oil pump should be stored in a dry, clean and non-corrosive environment.

3. The gear oil pump should be checked and repaired frequently. The electric oil drum pump should be checked and repaired frequently. The power cord must be checked: internal wiring, plug, switch are in good condition, insulation resistance is normal, brush tailstock is loose, commutator and electric brush The contact is good, whether the armature winding stage expansion stator winding is properly interrupted, whether the bearing and rotating parts are damaged, etc.

4. Pay attention to the insulation resistance of the gear oil pump. For electric pumps that have been left unused for a long time or used in a humid environment, the insulation resistance of the windings must be measured with a 500 volt megohmmeter before use.If the insulation resistance between the winding and the motor case is less than 7 megohms, the winding must be dried.

5. Keep every part and replace the same parts. When disassembling and inspecting the gear oil pump, keep every part well. Pay special attention to the flameproof surface of the flameproof parts so that they cannot be damaged, including insulating gaskets and bushings, if any If it is damaged, it must be replaced with new identical parts. Substitute materials with lower raw material properties or parts that do not conform to the original specifications shall not be used. All parts shall be installed in the original position during assembly, and shall not be omitted.

The URL of this article: http://www.sccjyy.cn/news/405.html

Key words:Gear pump,Gear pump price,Gear pump manufacturers

Recently Viewed:

- Research on Application and Development of Hydraulic Control Technology

- Caring for employees, caring for health and long-term solution, organizing all employees to conduct health examinations

- How long can the gear pump of the hydraulic system work? From what aspects can it be analyzed?

- Analysis of Causes of Common Gear Pump Bearing Failures

- Changjiang Hydraulics won the title of "2018 Outstanding Contribution Award for Economic Development" in the High-tech Zone

- Summary of maintenance and repair points of hydraulic cylinders

Related Products:

related news:

- Measures to reduce vibration and noise of gear pump

- Reasons for the motor heating during the use of the gear pump

- Causes of noise in gear pumps

- What is the difference between a gear pump and a screw pump?

- Press the "accelerator key" for epidemic prevention and production

- What are the techniques to prevent the gear pump from clogging?

- Changjiang Hydraulics won the title of "Demonstration Enterprise for Establishing Modern Enterprise System"

- What are the sealing methods for Luzhou hydraulic gear pumps?

- Contact strength and bending strength of gear oil pump

- What are the reasons for the gear pump oil seal being flushed out?